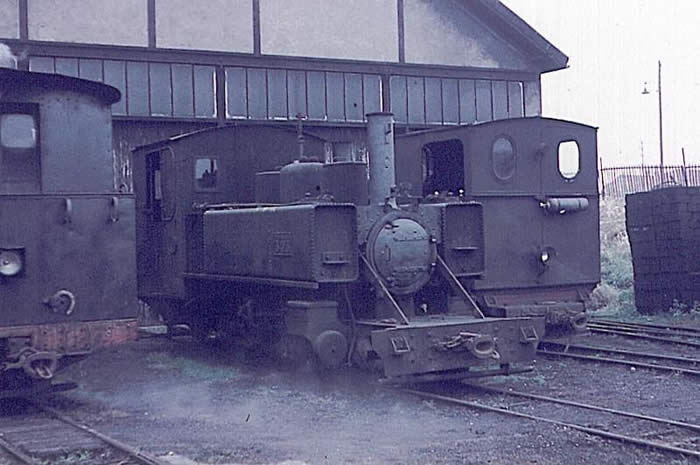

ALCO Mountaineer 2-6-2 No 57156

built at the Cooke Works of the American Loco Corporation in 1916

and used to transport people and goods to and from the Somme,

where it was given the number 1265 by the WDLR (War Department Light Railways).

After the war it was used on a sugar refinery in France.

John Ransom of the London Area Group of the Festiniog Railway purchased the loco in the 1960s. The loco was moved to the FR where it entered service in 1967. At the Festiniog, Mountaineer has been rebuilt several times.The smokebox was extended beyond the tanks in 1970. Oil firing was installed in 1972 followed by superheating and piston valves, and a new boiler in 1983. Other modifications consisted of a re-profiled cab with sloping sides above waist height to allow passage through Garnedd Tunnel.

The cab was re-profiled in the Fairlie pattern in 1983. At the same time the large ejector exhaust was routed up the rear of the chimney. New cast brass nameplates were fitted and the repaint included the standard red line between black and green.

photo Gerv Wright

The above version is the one I have aimed at.

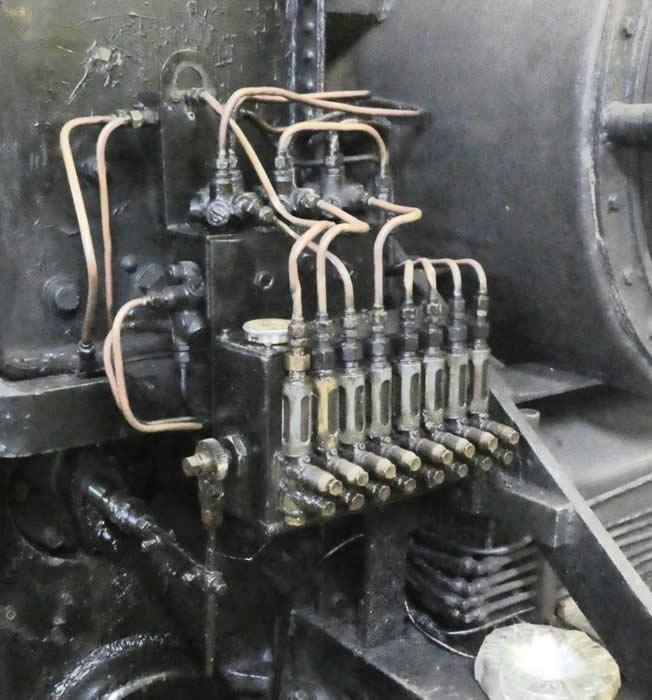

In 2021 on a visit to the FR I was lucky enough to arrange for a viewing of Mountaineer in its Shed at Glan y Pwll.

But before this I was kindly given access to photographs and measurements that Lyndon Smith had taken on a much earlier visit.

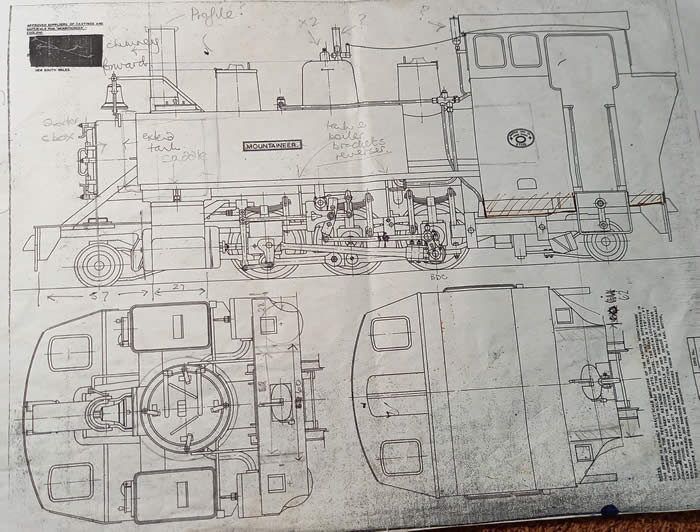

I used a GA drawing of a 71/4 loco by Don Young; rescaled by Mathhew Widdop. This was of the earlier "headbanger version."

And then, of course, the many photograhs I had been sent by

Andy Wilkinson, Trev Oughton and Gerv Wright.

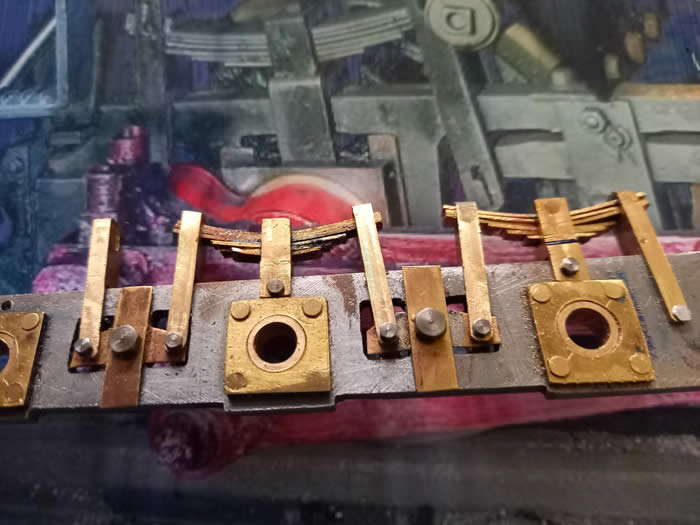

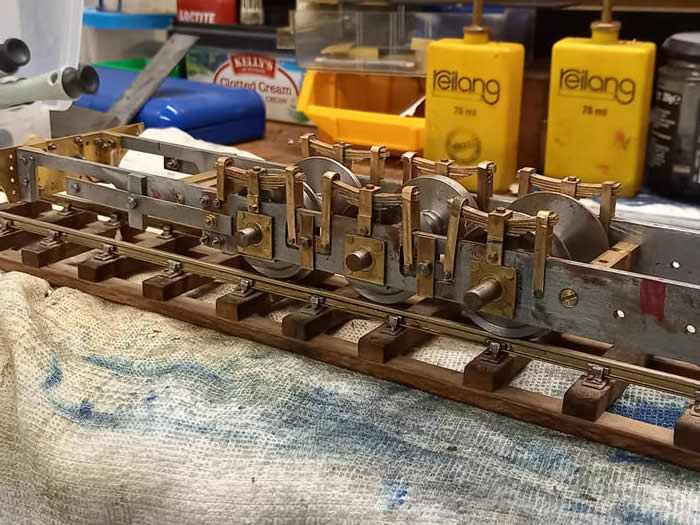

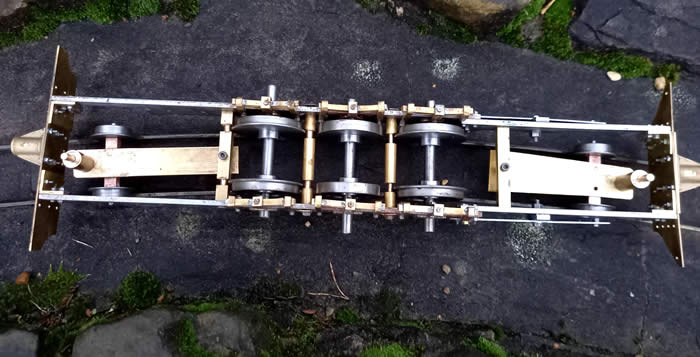

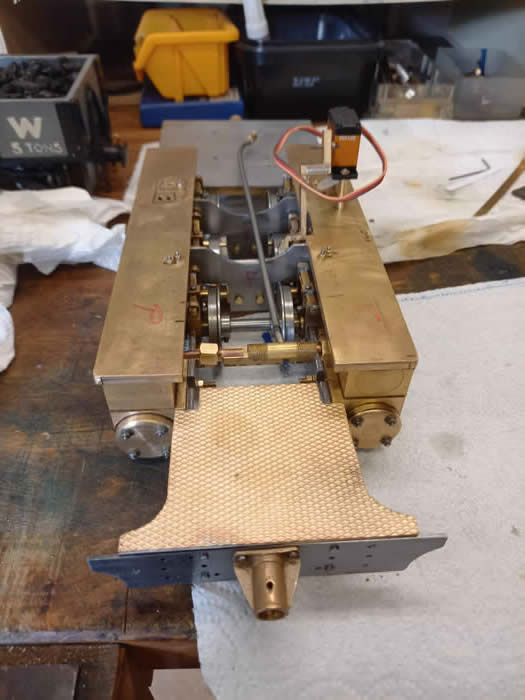

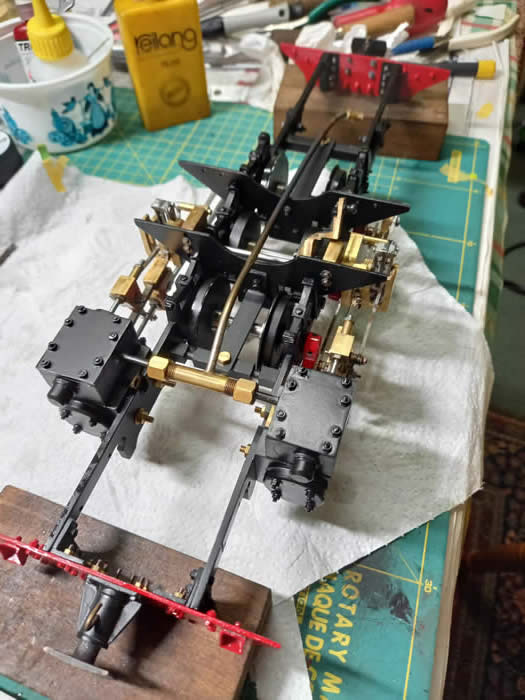

Mountaineer uses bar type frames. These were milled out of 3mm mild steel.

The chassis is 330mm long.

The wheels were made to a bespoke diamemter by Stephen Lacey of Essel Engineering. The brass cast spring buffers also came from Essel.

Axle bearings are phosphour bronze.

I made the leaf springs as per the prototype

Rolling chassis

Pony trucks with 20mm wheels [ IP engineering ] were tested on the LLR curves. Note sprung plungers.

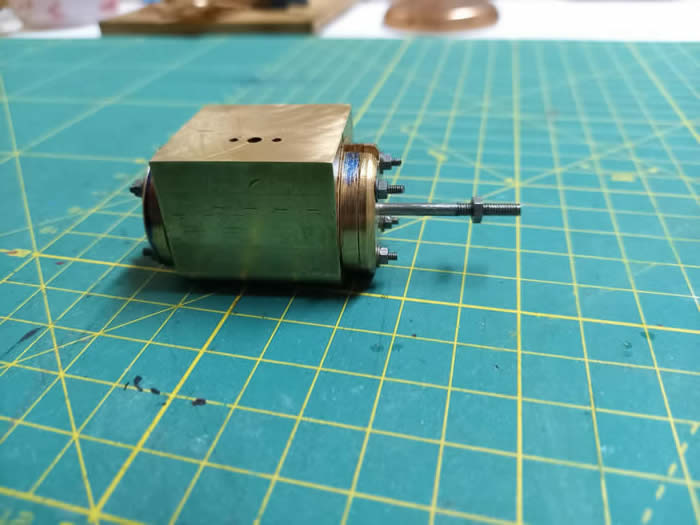

Cylinders were 9/16 diameter from 11/4 brass square with 3/32 piston rod

The gland is sandwiched between the two rear end covers. Steel studding used to secure end caps.

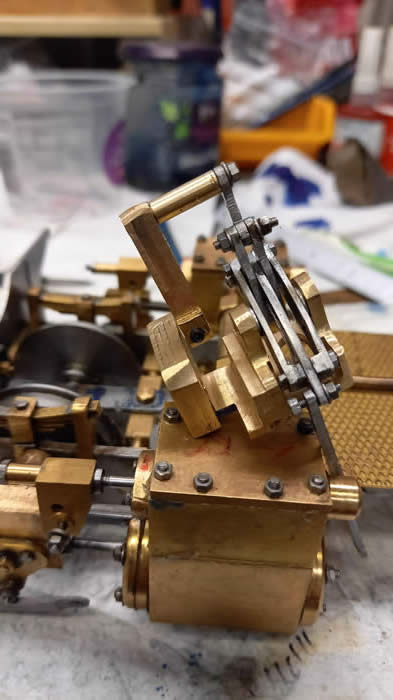

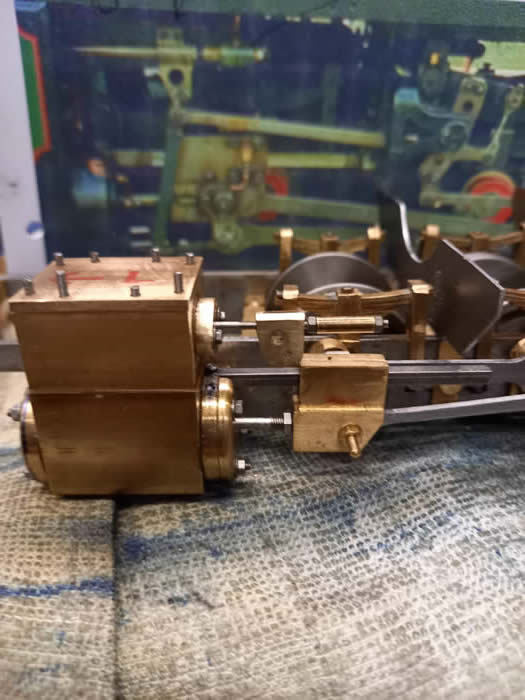

The steam chest : originally a 1/16 valve rod. This was replaced in the final version with a 3/32 rod. The rod is supported at both ends [ as on the prototype ] The combination bracket is resting on top of the steamchest.

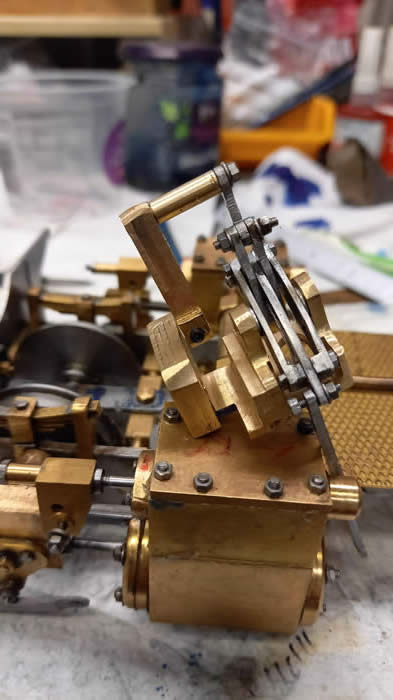

Now the slidebars and crosshead

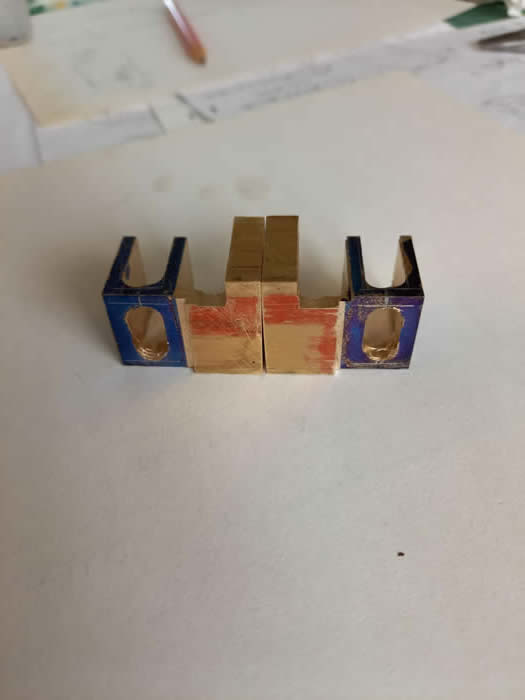

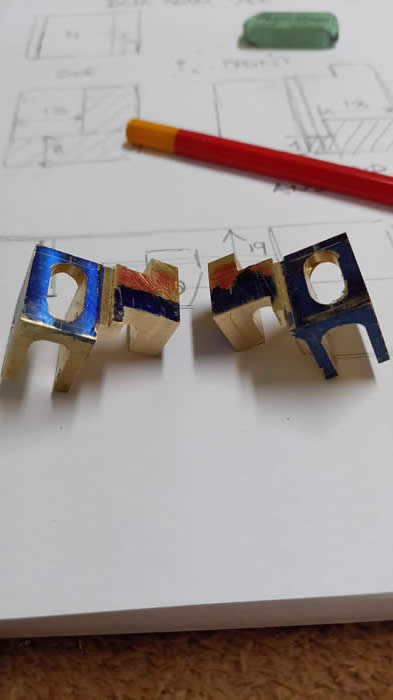

Crossheads for piston rod and valve rod

The combination bracket is bolted to the front bracket supporting the boiler.

Walshaerts valve gear has a central radius rod, and the lifting link is at the rear.

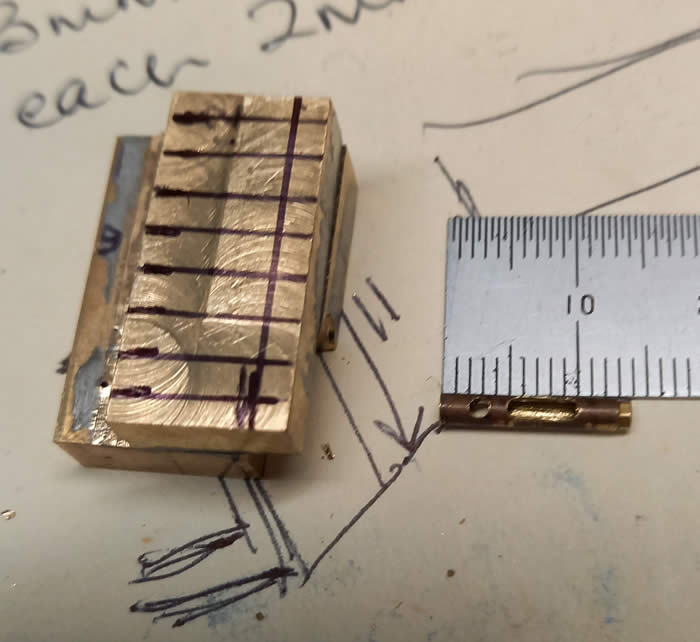

The combination bracket was milled from a solid piece of brass one inch square

Combination brackets before bolting to the boiler support bracket

showing weighshaft which passes underneath the boiler [ just! ]

Lifting arm and lifting link on top of steamchest

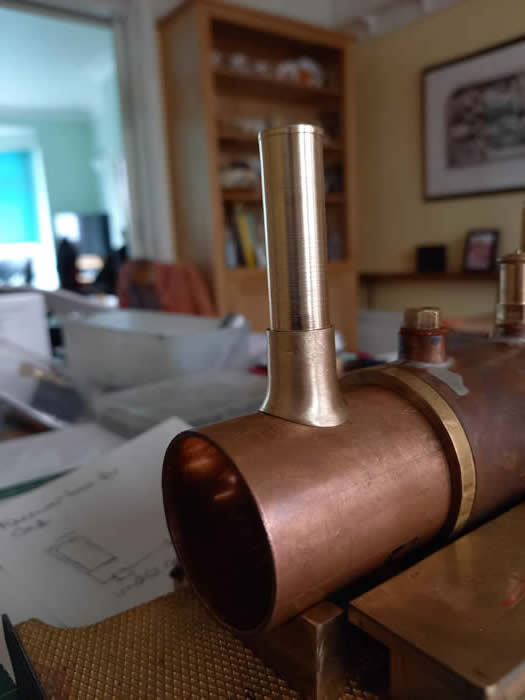

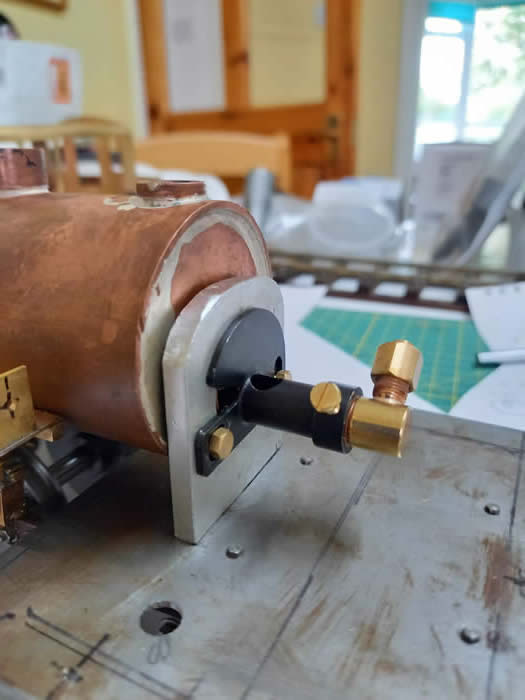

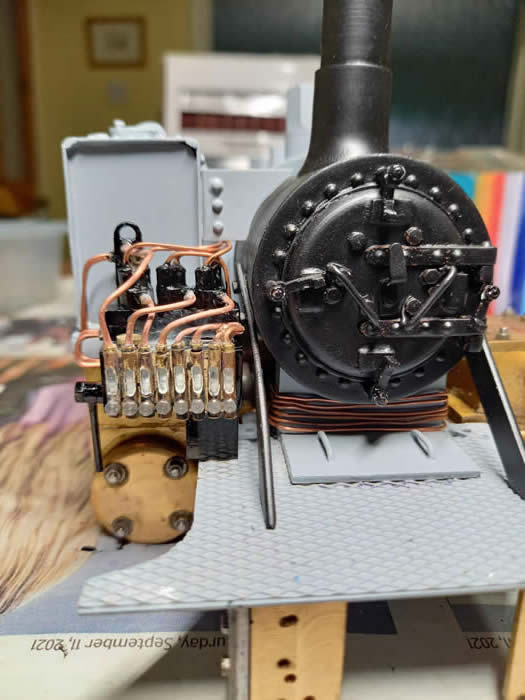

The boiler was made from 2" tube with phosphour bronze bushes

and a 19mm flue tube

Chris silver soldered it all together

Trev Oughton loaned his testing equipment before the boiler was officially passed by Rodger Schofield, one of the boiler testers in the Yorkshire Group

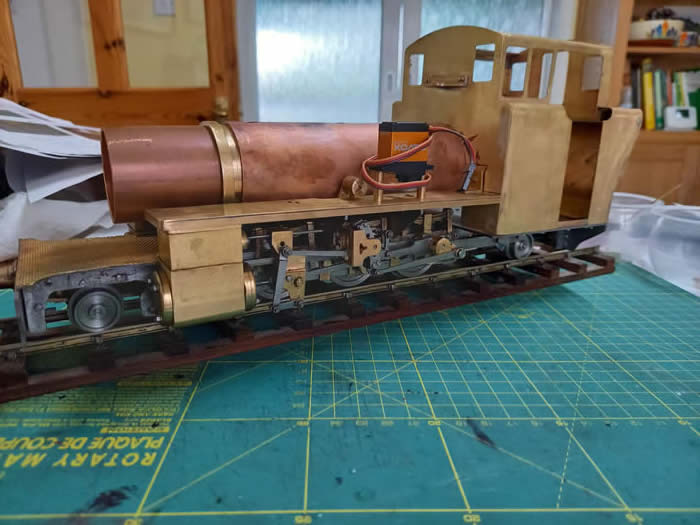

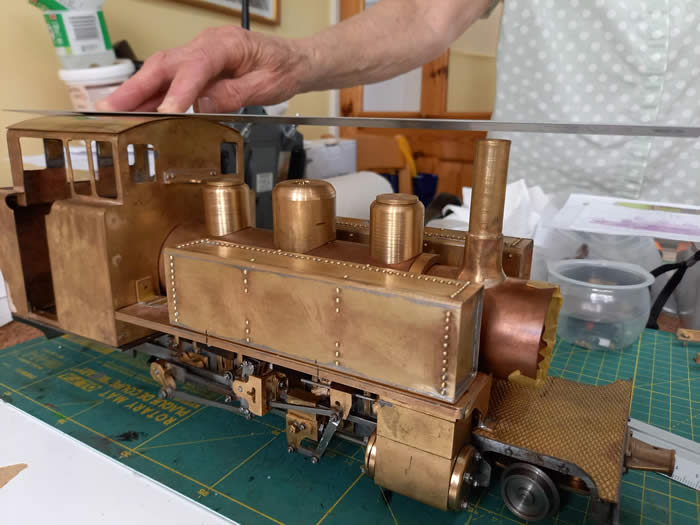

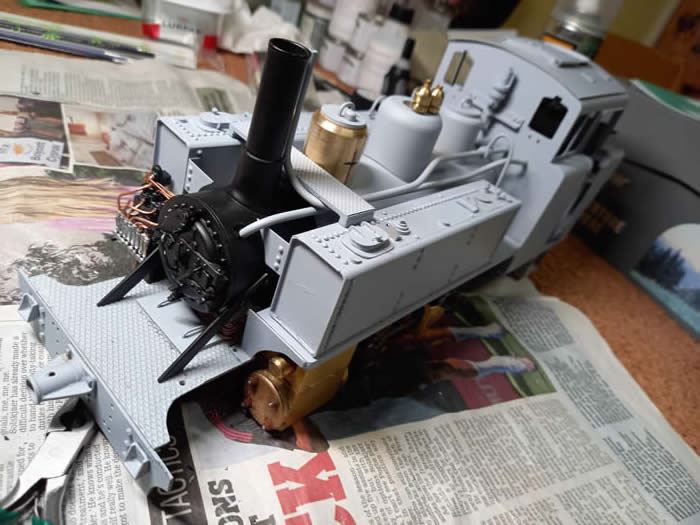

By May 2021 the boiler could be trial fitted with the cab.

The scale size of the smokebox is 13/4" so I made a brass ring to step down

the smokebox from the boiler. This "bodge" is covered up on the finished engine by the " platform " behind the chimney.

The opening smokebox was made as close to scale as possible with 4 locking handles

Stove pipe chimney

Front and rear footplates. Footplates for tanks.

Diamond pattern brass from Swift Sixteen

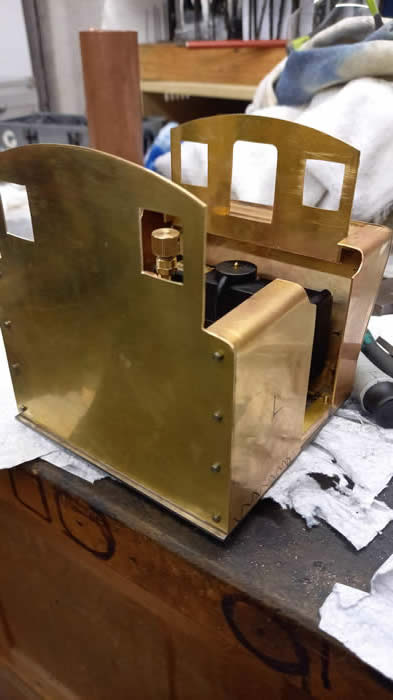

Cab parts

Sides soldered together

side tanks

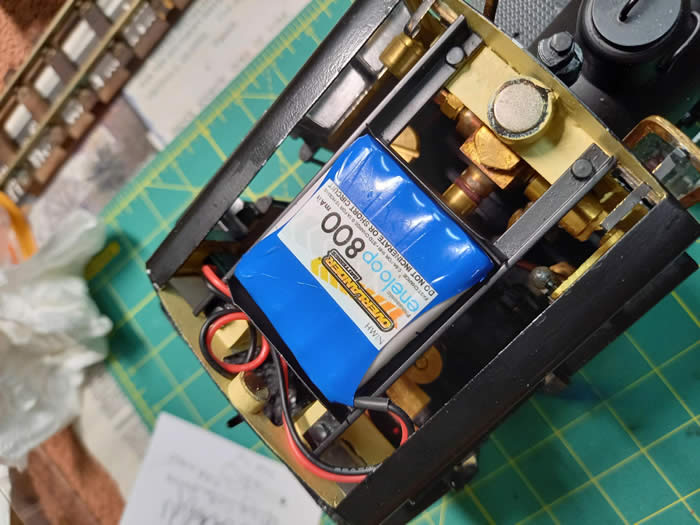

Roundhouse Type D gas tank fitted into the bunker space

Battery tray

trial fitting

Rear boiler support and Roundhouse burner

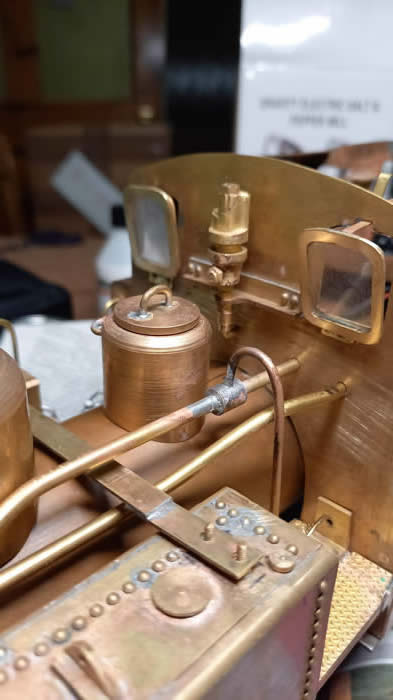

Cab layout ..showing lubricator and whistle valve

Both front and rear of cab has magnets mounted for securing the roof

The switch was placed in the bunker ....a coal version when Mountaineer is restored to duty!

Window and whistle detailing

Imm bore brass bevel gears from China for the front sand dome

which also houses a Goodall top up valve

Cab side windows were milled from solid perspex to fit flush with the cab sides

boiler clack valve

whistle- several tones

Oiler

A tricky bit of scratch detailing using 3/32 brass tube and 1mm perspex rod inside and 10ba bolts

I tried to get all the correct pipe runs

Of course when you have a working chassis that has been successfully tested on steam you have to take everything apart to begin painting..chassis but with dummy axles to keep out the paint

Matt black cellulose from One Stop paints for the chassis, boiler and smokebox

Chassis reassembled, retimed and steam tested using the boiler from my Pearse "Countess"

Looking smart in primer

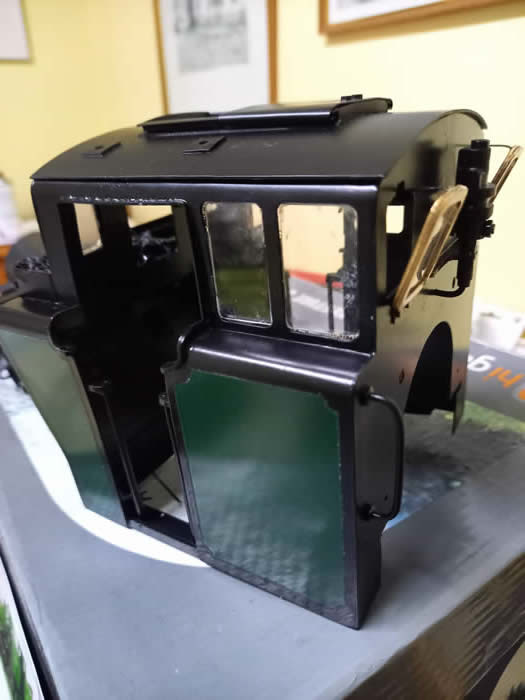

Satin black for the tanks and cab

All the parts painted black

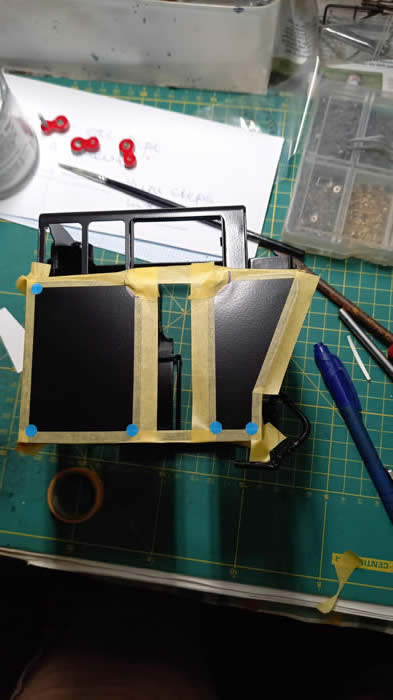

Tanks were masked with Tamiya tape and masking dots used at the corners for the small curves

Cab sides being masked

Green cellulose Mid Brunswick Green Satin

Chris did the red lining

January 2022 at Charminster - full lining applied

The works and name plates were made by Gerv Wright.

FR crests by www.precisionlabels.com

Decided to paint brass parts with steel paint..yet to be tested

Mountaineer was completed and tested in January 2022

And then stripped because I decided to put cork lagging around the boiler!

The return cranks were also improved by making them in mild steel.

Photo : Jack Hartwell