Materials :

1" x 16swg Copper tube for the boiler

1" brass round

from Macc Models [ see Traders ME suppliers ]

Dry Acid Pickling crystals 750grams

CUP ALLOYS 1mm 455 630-660 degrees C and EF FLUX 550-800 degrees C melting range

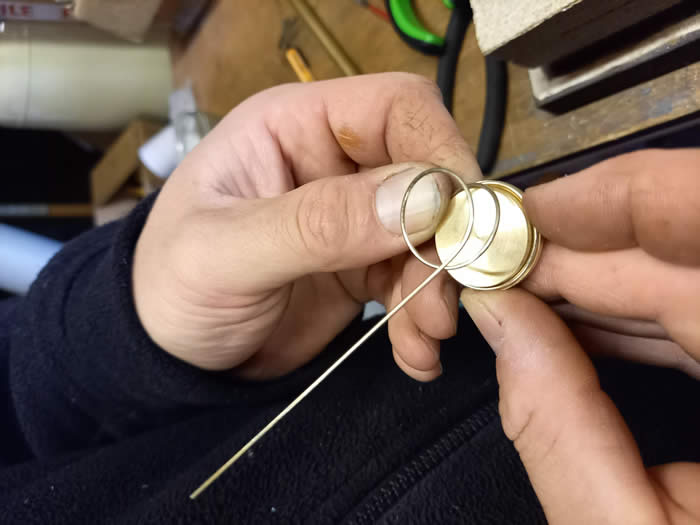

Make silver solder "templates" for ends using a slightly smaller bar so they are a tight fit

Tank body 16swg x 1" copper tube 72mm long

Ends : top 6mm with M4.5 x 5 thread for Ronson Valve

Bottom 2mm Total height 80mm

Both turned 3mm to fit into the tube

Ronson valve from Roundhouse Engineering

Note the top has a "ring" with a hole for the 1/8 pipe in the

only in the outer section

Apply flux

clamp allows the gas tank to be turned when hot

repeat for bottom and add pipe to suit

Further advice from Trev Oughton

Chamfer so that the solder " circle " flows better into the joint

File the 1/8 copper pipe to a half circle

and countersink the entry hole

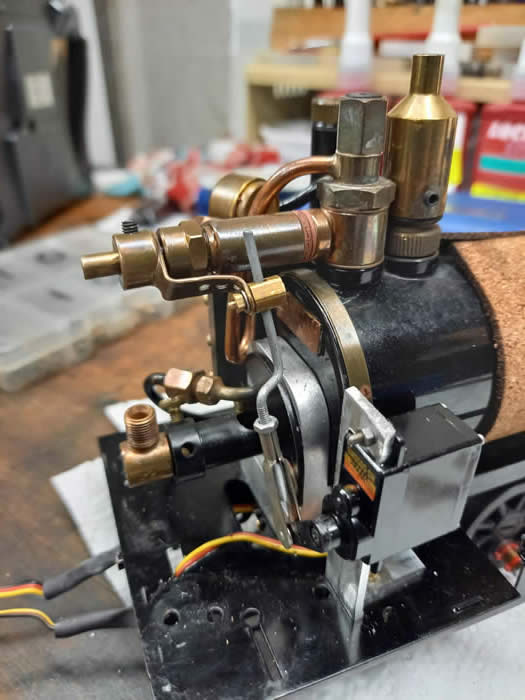

The original Roundhouse tank.

Note the filler and the output to the gas valve are separate.

Capacity 18ml approx.

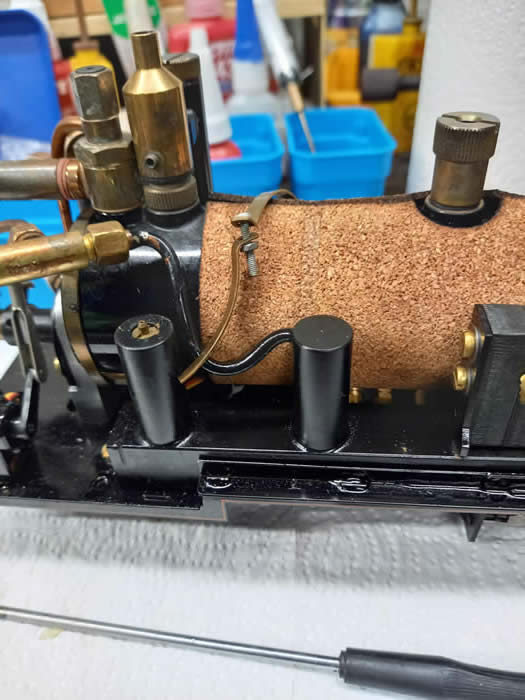

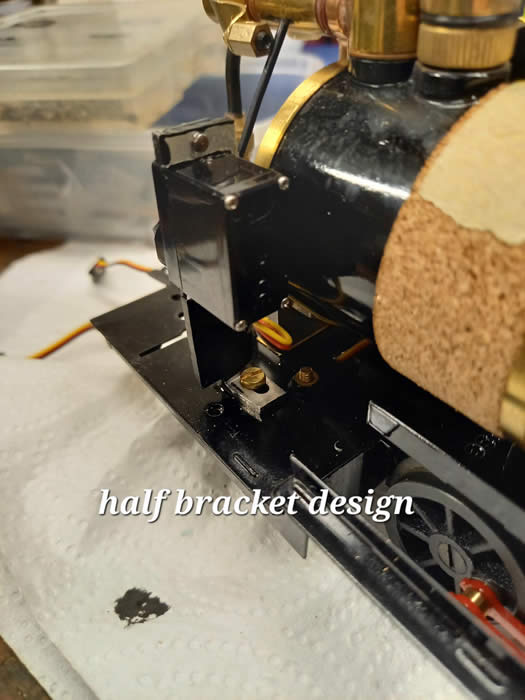

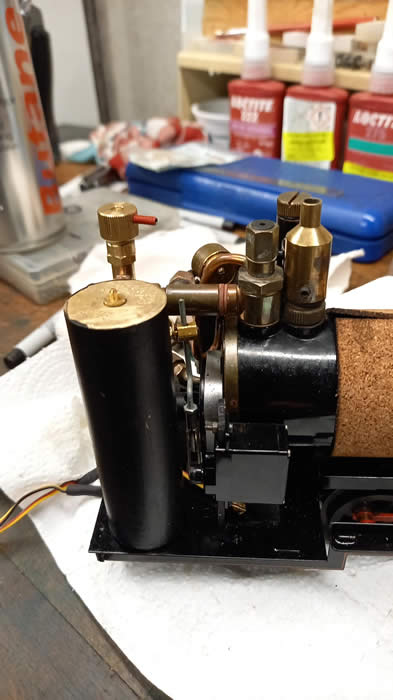

Servo remounted using alumimium angle.

Original regulator and servo fittings reused.

Gas tank painted and mounted;

re-use RH gas filler valve

Roundhouse gas regulator reused with longer 6ba grub screw.

No longer sticks out of the cab side.

You will have to remove some of the cab fixing tabs but there are still plenty to go round including two at the front of the loco holding the saddle tank .

End result :

A conversion which locates the tank to be in a cooler place

at the rear of the cab. The gas can be turned right down so that the loco does not blow off as easily. The gas valve is now inside the cab.

Parts are reused.

The loco lights easily.

The loco can be re-gassed when hot.

Running time is 35+ minutes.

[ Chris Cooper holds the small England "record" with 51 minutes. Timed by Jack Hartwell on 4 August 2024. Method: Fill gas tank half full approx; light burner and bring up pressure to 40psi; turn burner off; re-gas until gas filler vents; relight burner and run with no blowing off and topping up water little and often. Run achieved with a scale FR Victorian train ]

Replacement tank capacity 27ml approx.

Total cost approx £25 [ 2024 ]

Prince

Design and soldering by Chris Cooper

Gas tank parts made by Andy Cooper

Tested by Rodger Schofield

October 2022

Boiler and gas tank testing

Rodger Schofield [ Huddersfield and area ]

can be contacted on rschofield46@talktalk.net

Boiler testing only

Derek Round [ Bradford and area ]

can be contacted on roundd@sky.com